6OH5OH IS A ONE-PERSON WORKSHOP CREATING SMALL-BATCH, 3D-PRINTED GEAR.

From the Mini VX™ action camera cage for GoPro, DJI Action, and Insta360 to 3D-printed fingerboard decks, ramps, and obstacles, everything is designed, printed, and assembled in-house by Mark Andrew in California. Built for skateboarding, filming, and collecting — made one at a time.

The Mini VX™ is a 3D-printed action camera cage built for skate filming — combining the VX1000 look with the convenience of modern GoPro, DJI, and Insta360 cameras. Designed and produced in small batches in California, each rig features a skate-ready top handle, durable PETG construction, and a distinctive 6oh5oh aesthetic.

Alongside the Mini VX™, 6oh5oh makes 3D-printed fingerboard decks, ramps, and filming accessories, all created in-house with hand-drawn artwork and precision additive manufacturing. Explore the full Mini VX™ ecosystem, learn how each rig is made, and find filming guides designed specifically for skateboarding.

-

MINI VX™ CAGE

Regular price $83.00 USDRegular priceUnit price per -

MINI VX™ CAGE LIMITED DROP - CHRISTMAS EDITION 🎄

Regular price $103.00 USDRegular priceUnit price per -

LIMITED EDITION GARAGE SERIES – 1/4 - VOLVO 244 GL

Regular price $35.00 USDRegular priceUnit price per -

MINI VX™ CAGE LIMITED DROP - CRYSTAL 💎

Regular price $103.00 USDRegular priceUnit price per -

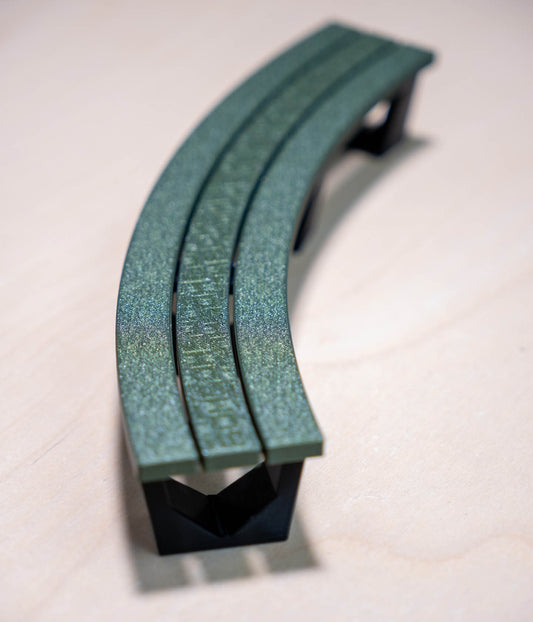

CURVED BENCH

Regular price $15.00 USDRegular priceUnit price per -

6OH5OH KICKER

Regular price $12.00 USDRegular priceUnit price per -

FB DECK THIN 32MM (CHOOSE YOUR KICKS & CONCAVE)

Regular price $15.00 USDRegular priceUnit price per -

FB DECK MEDIUM 34MM (CHOOSE YOUR KICKS & CONCAVE)

Regular price $15.00 USDRegular priceUnit price per -

FB DECK WIDE 36MM (CHOOSE YOUR KICKS & CONCAVE)

Regular price $15.00 USDRegular priceUnit price per -

TRAFFIC CONE - GLOW-IN-THE-DARK

Regular price $10.00 USDRegular priceUnit price per -

MINI VX™ STICKER PACK

Regular price $8.00 USDRegular priceUnit price per -

Sold Out

Sold OutFINGERBOARD SKATEPARK V2

Regular price $110.00 USDRegular priceUnit price per

🎄CHRISTMAS MINI VX™

THE MINIVX™... BUT FESTIVE

BUILT FOR FILMERS WHO WANT SOMETHING SPECIAL FOR THE HOLIDAYS.

Collapsible content

LIMITED BY DESIGN

Every 6oh5oh release is intentionally produced in small batches. I design, print, and assemble everything myself, which means every run has a natural limit — not because of hype, but because of the hands-on work that goes into each piece.

This approach keeps quality high and waste low. Filament, test prints, and failed parts get recycled back into the workflow whenever possible, and each product is only made in the quantities I can personally print and finish to the standard I’m happy with.

Whether it’s a Mini VX™ colorway, a fingerboard from the Garage Series, or a limited seasonal drop, each run is finite, personal, and made by one person — not a factory.

It’s gear you can feel good about owning, built with care instead of mass production.

FROM SKETCH TO FINAL PRINT

Everything at 6oh5oh starts with a real session — a problem to solve or an idea that would make filming or fingerboarding more fun.

Most designs begin as rough sketches and notes, then move into 3D modeling where I dial in the shape, fit and function for cameras, phones or fingerboards. From there, I print and test multiple prototypes in-house, making small tweaks until the parts feel right in the hand and on a session.

Once a design is locked in, every piece is 3D printed, finished and assembled in my own workspace using durable materials.

For graphic pieces (decks, cases, stickers), the artwork is drawn by hand first, then translated into digital linework or even built directly into the 3D-printed surface so it doesn’t just sit on top — it’s part of the object.

The result is a small-batch run of gear that’s built to be used, not just displayed — camera rigs like the Mini VX™ action camera cage and its accessories, 3D-printed fingerboard decks, ramps and obstacles, plus limited edition drops and collabs.

Each product is made with the same approach: practical, tested, and made by one person who actually uses this stuff.